Jute ICARE

Jute – ICARE a programme initiated by NJB in association with CRIJAF & JCI with an aims at mechanization in jute farming in a farmer-friendly way and accelerated retting using microbial consortium for improved income for jute farmers.

Objective :

The objective of the project is to support the small and marginal jute growers with adequate pre and post harvesting operations so that they can grow good quality jute & receive higher price for their produce. The continuation of the project will also make the growers aware about the latest technologies in the country.

To institutionalize the use of scientific agronomic techniques and practices, which would be imparted to the jute growers, the following inputs shall be provided :

1. 100% Certified Seeds at subsidized rate.

2. Demonstration of scientific jute cultivation practices for adoption at farmers' field with mechanical intervention distribution of seed drill / Nail Weeder/Cycle Weeder.

3. Demonstration of Microbial retting using CRIJAF SONA, a microbial consortium and also distribution to the farmers.

Jute ICARE Phase VII (2021) – Coverage

| Sl. No. | Description | 2021 |

| 1. | Area of Land Covered | 125000 Hector |

| 2. | Total Farmer Registered | 300000 |

| 3. | No. of Jute Growing Block Covered | 141 |

| 4. | Seed Drill +Cycle Weeder | 1000+1200 |

| 5. | CRIJAF-SONA/ NINFET-SATHI ( Retting Accelerator) | 655 MT |

| 6. | Training Demo / Field Demo | 726 |

| 7. | Jute Seed (certified new variety) | 35 MT* |

*731 MT of certified seedshas been supplied to the farmers by JCI under its commercial operation.

Agriculture & Raw Jute

Jute is a bio degradable crop grown mainly in the Ganges delta. It is one of the most important natural fibers after cotton in terms of cultivation and usage. Major parts of West Bengal and Bangladesh are involved in Jute cultivation. Countries like China, Thailand, Myanmar, Nepal and Bhutan also cultivate Jute.

CULTIVATION

Jute is a crop which requires huge rainfalls. It requires alluvial soil with stagnant water. It requires maximum water during the sowing period. The suitable climate for growing jute (warm and wet climate) is during the monsoon season. Temperatures from 20˚C to 40˚C and relative humidity of 70%–80% are necessary for successful cultivation. Jute requires 5–8 cm of rainfall weekly.

White Jute(Corchorus capsularis)

Several historical documents (including,Ain-e-Akbariby Abul Fazal in 1590) state that the poor villagers of India used to wear clothes made of jute. Simple handlooms and hand spinning wheels were used by the weavers, who used to spin cotton yarns as well. History also states that Indians, especially Bengalis, used ropes and twines made of white jute from ancient times for household and other uses. It was also used for transporting agricultural goods.

Tossa jute (Corchorus olitorius)

Tossa jute (Corchorus olitorius) is a variety of jute in which India is the leader. It is used both for fibre and eating purpose. Tossa jute fiber is softer, silkier, and stronger than white jute. This variety astonishingly shows good sustainability in the climate of the Ganges Delta. Along with white jute, tossa jute is also cultivated in the soil of Bengal. Currently, India and Bangladesh is the largest global producer of the tossa jute variety.

History

Jute has been used since ancient times in India. During the 19th and early 20th centuries jute was indispensable. It was used in making sacks, ropes, boot linings, aprons, carpets, tents, roofing felts, satchels, linoleum backing, tarpaulins, sand bags, electric cable, and even parachutes. Jute appealed to the people because of its strength, low cost, durability and versatility.

During the British Raj, most of the raw jute fiber of Bengal was taken to the United Kingdom, where it was then processed in mills concentrated in Dundee. Margaret Donnelly, a jute mill owner in Dundee, set up the first jute mill in Bengal. In the years 1950s and 1960s, when nylon and polythene were rarely used, one of the primary sources of foreign exchange earnings was the jute products.It was also used in military during the British regime.

Of late, Jute has entered diverse sectors of industry, where natural fibers are gradually turning better substitutes. Among these industries are paper, celluloid products (films), non-woven textiles, composites (pseudo-wood), and geotextiles. In December 2006 the General Assembly of the United Nations proclaimed 2009 to be the International Year of Natural Fibers, so as to raise the profile of jute and other natural fibers.

However, the sudden rise of polythene and other synthetic materials as a substitute for jute increasingly captured the market and jute industry suffered a setback.

Climate and Soils

Jute requires a warm and humid climate with temperature between 24° C to 37° C. Constant rain or water-logging is harmful. The gray alluvial soil of good depth, receiving salt from annual floods, is the best for jute. Flow ever jute is grown widely in sandy loams and clay loams.

Sowing of jute

Sowing of jute in midlands and high lands starts with showers in March and continues till early June. Compost, Phosphorus and Potash, Urea, Nitrogen fertilizers are used as a fertilizers. It also requires 500mm of water.

Harvesting

Jute is harvested between 120 days to 150 days from sowing when the flowers have shed. Early harvesting gives good healthy fibers. The harvested plants are left in field for 3 days for the leaves to shed. The stems are then made up into bundles for steeping in water. Steeping is carried out immediately after harvest.

RETTING

Retting is the process of extracting fiber from stem of the plants. The various ways of Retting are:

Mechanical retting (hammering), chemical retting (boiling & applying chemicals), steam/vapor/dew retting, and water or microbial retting. Among them, the water or microbial retting is a century old but the most popular process in extracting fine fibers. However, selection of these retting processes depends on the availability of water and the cost of retting process.

To extract fibers from jute plant, a small stalk is harvested for pre-retting. Usually, this small stalk is brought before 2 weeks of harvesting time. If the fiber can easily be removed from the Jute core, then the crop is ready for harvesting.

After harvesting, the jute stalks are tied into bundles and submerged in running water. The stalk stays submerged in water for around 20 days. However, the retting process may require less time if the quality of the jute is better. In most cases, the fiber extraction process of fibers in water retting is done by the farmers standing under water.

When the jute stalk is well retted, the stalk is grabbed in bundles and hit with a long wooden hammer to make the fiber loose from the jute. After losing the fiber, the fiber is washed with water and squeezed till the last drop of water. The extracted fibers is further washed with fresh water and allowed to dry on bamboo poles. Finally, they are tied into small bundles to be sold into the primary market.

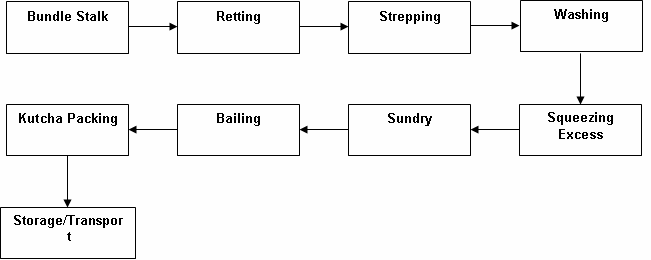

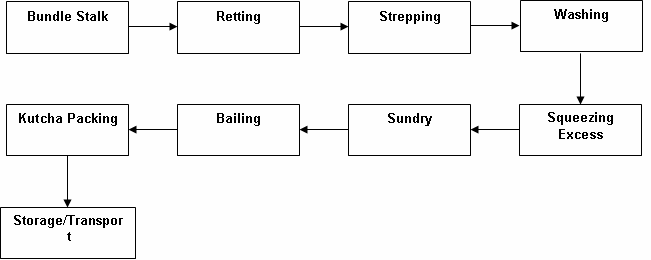

The Fibre Extraction

The jute plant's fibers lie beneath the bark and surround the woody central part of the stem.To extract the fibers from the stem, the process is carried out in the following stages:

USES OF JUTE

Fibre

Jute is the second most important vegetable fiber after cotton not only for cultivation, but also for various uses. Jute is used to make sacks and coarse clothes and also being used for wrapping bales of raw cotton. Jute yarns are woven into fine fabrics to use as curtains, chair coverings, cheap quality rugs, hessian clothes, backing of linoleum and carpets. Jute was mainly used for making sacks but now things have changed and many other ways of utilizing jute has come up.

Jute began to lose its popularity with the advent of synthetic materials as the latter was more economical. But slowly people began to realize the negative impact of synthetic materials on the environment. Jute scores over synthetic materials largely due to its bio-degradable nature. Examples of such uses include containers for saplings, which can be planted directly with the container without disturbing the roots, and land restoration where jute cloth prevents soil erosion.

The fibers are used to make ropes. Jute rope has long been popular in Japan for use in bondage. Jute butts, the coarse ends of the plants, are used to make cheap clothes. It also helps in addressing the problem of deforestation as it also makes. Jute has a long history of use in the sackings, carpets, wrapping fabrics (cotton bale), and construction fabric manufacturing industry.

Jute can be used to create a number of fabrics such as Hessian cloth, sacking, scrim, carpet backing cloth (CBC), and canvas. Hessian, lighter than sacking, is used for bags, wrappers, wall-coverings, upholstery, and home furnishings. Sacking, a fabric made of heavy jute fibers, has its use in the name. CBC made of jute comes in two types. Primary CBC provides a tufting surface, while secondary CBC is bonded onto the primary backing for an overlay.

Diversified jute products are becoming more and more important to the consumer today. Among these are gift articles, handicrafts, wall hangings, shopping & carry bags, floor coverings, home textiles, high performance technical textiles, Geotextiles, composites etc.

Jute floor coverings

They consist of woven and tufted and piled carpets. Jute Mats and mattings are commonly woven in Southern parts of India. Jute Mats & Rugs are made both through Power loom & Handloom, in large volume in Kerala, India décor.

Jute has clear advantage over cotton. It is a strong, durable and light-fast fiber. It has features like UV protection, heat insulation, low thermal conduction and anti-static properties make it a wise choice in home furnishing. Also, fabrics made of jute fibers are naturally decomposable. This can make jute an important part of the textile industry.

Jute grows very fast as compared to other products. It hardly takes 4-6 months. Cellulose produced from jute can be used to suffice the demand of wood around the world. Jute is a crop which can save the planet from being polluted by the products which are produced by the polluting factories. Jute is the most eco-friendly as it is useful from the time it is seed to the time its fiber expires because of its bio-degradability feature.

Another diversified jute product is Geotextiles. It is one of the most important diversified product of jute. It is produced by blending jute with other natural fibers in fixed proportion and fabricated in definite pattern. They are also further treated with locally available chemicals according to need and life span. It has a moisture absorbing capacity. It is also very flexible and have good drainage properties. It can be used in soil erosion control, vegetation consolidation, protection of river banks and in road construction.

Jute bags

This is the most common use of jute.Jute has an advantage over polythene and paper bags as it is 100 % bio-degradable in case of poly bags and no trees are required to be cut if compared to paper bags.It can carry a lot more weight than polythene and paper bags.

Food

Jute leaves are consumed in various parts of the world. It is a popular vegetable in West Africa. The Yoruba of Nigeria call it "ewedu". The Hausa people of Nigeria and theirFulbeneighbors call it "rama." They use it to produce soup ("taushe") or boil the leaves and mix it with "Kuli-kuli" or groundnut cake and consume the mixture which they call "kwado" in Hausa. The Hausa peasant farmers cultivate it beside their corn-stalk constructed homesteads or among their main crops in their farms. There are commercial jute farmers in Northern and South Western Nigeria. They (jute commercial farmers) have a strong National Association registered by the authorities. In Northern Sudan it's called "Khudra" meaning green in Sudanese Arabic. The Hausa and Fulbe peoples also use jute leaves to treat some diseases. And the Songhay of Mali call it "fakohoy" whereas Tunisians call it mulukhiyah. It is made into a common mucilaginous (somewhat "slimy") soup or sauce in some West African cooking traditions, as well as in Egypt, where it is called mulukhiyya, Cypriots call it molocha - and that refers to food - in terms of fiber this would be unknown - and it is sometimes eaten as boiled vegetable with lemon and olive oil. . It is also a popular dish in the northern provinces of the Philippines, where it is known assaluyot. Jute leaves are also consumed among the Luyhia people of Western Kenya, where it is commonly known as 'mrenda' or 'murere'. It is eaten with 'ugali', which is also a staple for most communities in Kenya. The leaves are rich in betacarotene, iron, calcium, and Vitamin C. The plant has an antioxidant activity with a significant α-tocopherol equivalent Vitamin E.

Other Uses

Diversified jute products can also be used in cosmetics, medicine, paints, and other products.

Features of Jute

Jute fiber is 100% bio-degradable and recyclable and thus environmentally friendly.

It takes very short time to grow (4-6 months) which can be useful in growing other food crops.

It is a natural fiber with golden and silky shine and hence called The Golden Fiber.

It is the cheapest vegetable fiber procured from the bast or skin of the plant's stem.

It is the second most important vegetable fiber after cotton, in terms of usage, global consumption, production, and availability.

It has high tensile strength, low extensibility, and ensures better breathability of fabrics. Therefore, jute is very suitable in agricultural commodity bulk packaging.

It helps to make best quality industrial yarn, fabric, net, and sacks. It is one of the most versatile natural fibers that have been used in raw materials for packaging, textiles and non-textile construction, and agricultural sectors. Bulking of yarn results in a reduced breaking tenacity and an increased breaking extensibility when blended as a ternary blend.

The best source of jute in the world is the Bengal Delta Plain in the Ganges Delta, most of which is occupied by Bangladesh.

Advantages of jute include good insulating and antistatic properties, as well as having low thermal conductivity and moderate moisture regain. Other advantages of jute include acoustic insulating properties and manufacture with no skin irritations.

Jute has the ability to be blended with other fibers, both synthetic and natural, and accepts cellulosic dye classes such as natural, basic, vat, sulfur, reactive, and pigment dyes. The resulting jute/cotton yarns will produce fabrics with a reduced cost of wet processing treatments.

Jute can also be blended with wool. By treating jute with caustic soda, crimp, softness, pliability, and appearance of it are improved, aiding in its ability to be spun with wool. Liquid ammonia has a similar effect on jute, as well as the added characteristic of improving flame resistance when treated with flame proofing agents.

![हिंदी [Beta]](https://jute.com/welcome-theme/images/language/hi_IN.png)